27 Jul The Most Underrated Aspect of Manufacturing Services

So you’ve ordered a cost-effective custom machine or had an automation company build out a manufacturing line for you. Perhaps you’re in need of some CNC machining services and upon receiving your product, are confused about the construction, or some of the technical aspects of any related software. If the system documentation provided is poorly written or incomplete, you’re forced to call the company and waste precious time that could’ve been spent on growing your business or completing work that needs to be done.

What is System Documentation?

System documentation is a collection of reference texts that pertain to the operation and maintenance of a machine or software solution. This is especially important in the automation and manufacturing fields where the different parts and aspects of a machine must always be in harmony with one another so that the machine runs as efficiently as it possibly can. Consider that any downtime in a machine often equates to a loss of profit for businesses as total output and efficiency take a hit—not only due to the machine being out of commission but also due to the time and resources invested that are required to fix it.

The Virtues of Good System Documentation

System documentation is one of those things wherein many cases, by the time it is being referenced, there are issues that need to be resolved with the maintenance or performance of the machine or software in question. This is why you so often hear tales of poor system documentation, because, at the time of obtaining the “solution” or machine, it was not readily needed.

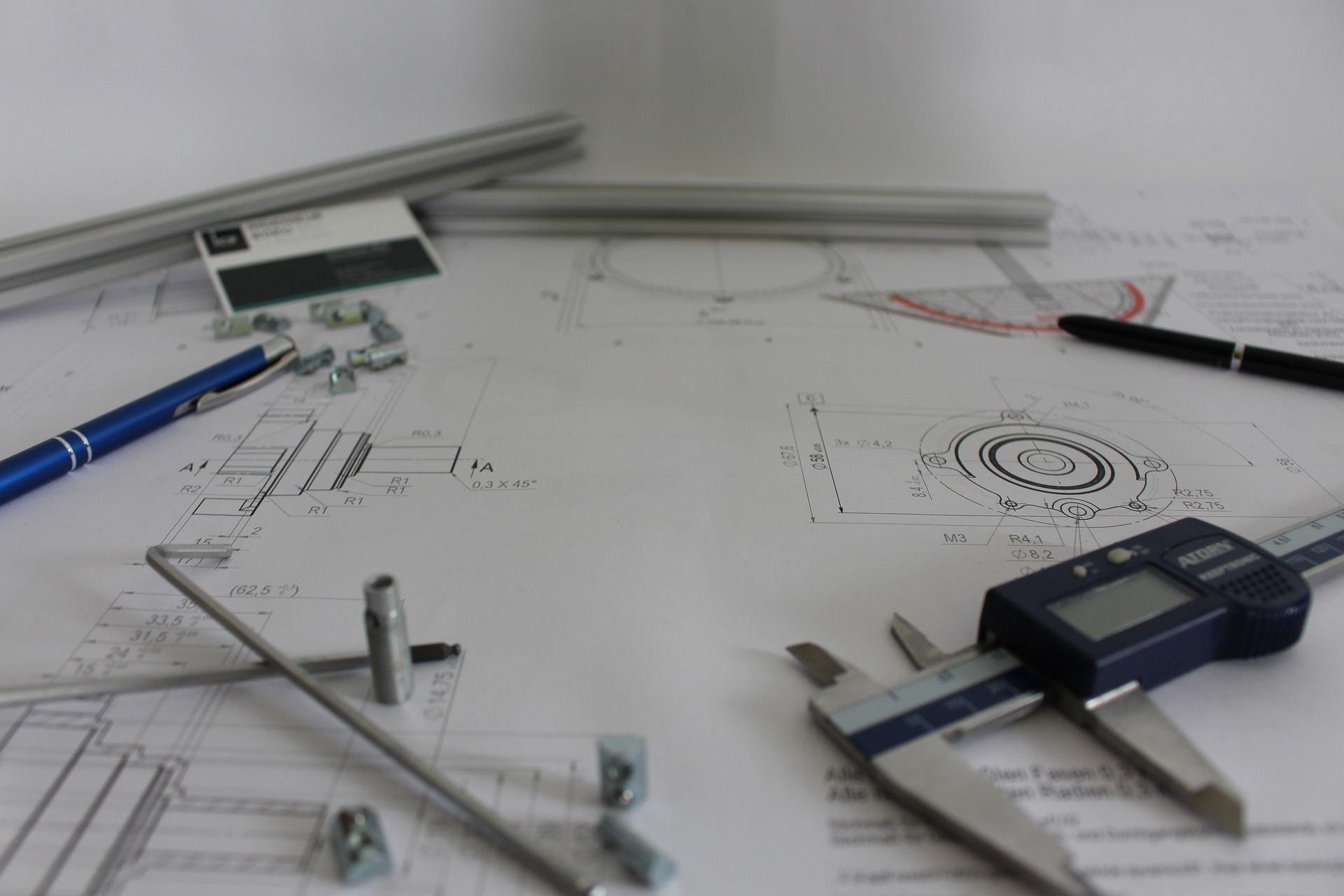

Good system documentation will detail many user case exceptions, that is, what to do when a specific issue arises. System documentation for machines will often include a list of components, what the components are made up of and what are the best practices for maintaining part integrity over the course of the machine’s lifetime. Typically, something called a bill of materials is included with the product/documentation so that companies know exactly what amount of labor went into the assembly of the product and the parts that were required—this is often a good explanation for the invoiced amount that it cost to produce the product.

Most importantly—especially when involving complex automation and machining, the system documentation should provide useful diagrams and information such as what spare parts are provided. When it comes to automation and machinery, the most critical part of maintenance is knowing how to service and replace specific parts that are causing the entire line to shut down or be less efficient.

Assembly Machine Design South FL

Automation Tech Support is a full-service tool engineering company. We can design and build any type of assembly or manufacturing/equipment used for machining. We pride ourselves on our robust system documentation practices for our clients. When you order from us, you’re not just getting a well-oiled machine that does what it’s supposed to do, you’re also getting a highly detailed bill of materials and documentation that outlines every component used in the construction of the machine so that your maintenance department has all the information they need to ensure that the product works well throughout its lifetime. We also provide a spare parts list so you don’t end up wasting money on a part you already paid for once.

If you’re interested in custom machines and cost-effective assembly lines, contact us at 561-737-3577!

Sorry, the comment form is closed at this time.